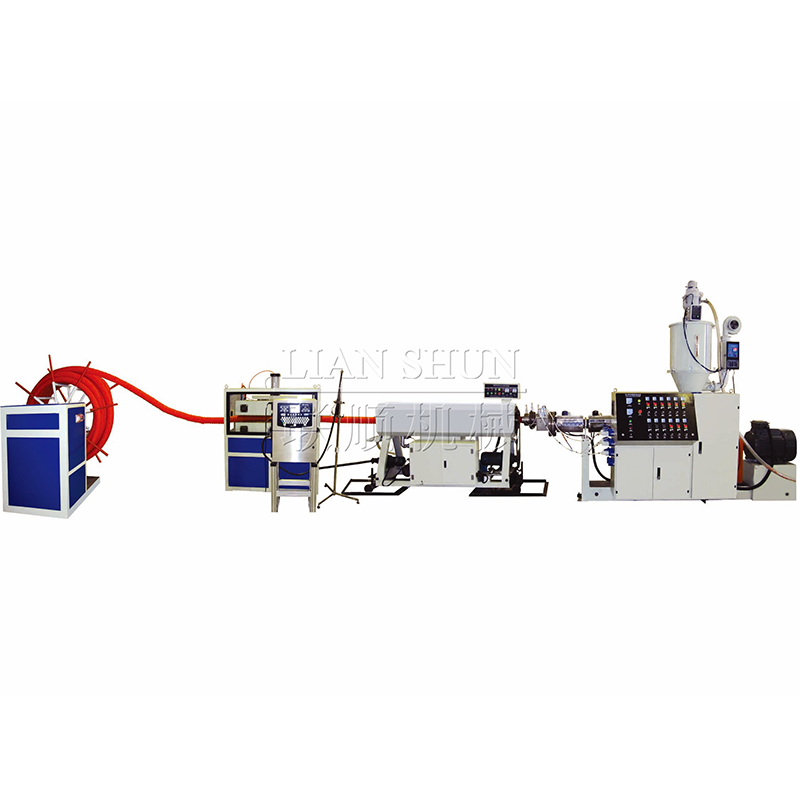

High-Quality Pipe Production Line for Efficient Manufacturing

By:Admin

With over 20 years of experience in the industry, Pipe Production Line has established itself as a trusted and reliable source for high-quality pipe production equipment. The company prides itself on its commitment to continuous improvement and customer satisfaction, and this latest release is a testament to that dedication.

The new line of machinery boasts state-of-the-art features designed to enhance efficiency, precision, and overall performance. From automated controls to advanced material handling systems, Pipe Production Line has spared no expense in ensuring that their equipment meets the highest standards in the industry. This level of innovation is set to streamline the manufacturing process, ultimately reducing production times and costs for companies that invest in this cutting-edge technology.

In addition to the technical advancements, Pipe Production Line has also focused on the environmental impact of their machinery. With a growing emphasis on sustainability and eco-friendly practices, the company has incorporated energy-efficient components and optimized processes to minimize waste and reduce carbon footprint. This aligns with the global push towards sustainable manufacturing practices and demonstrates Pipe Production Line's commitment to responsible production.

Furthermore, the company has also emphasized the flexibility and versatility of its new line of machinery. With customizable options and adaptable configurations, Pipe Production Line is well-equipped to cater to the diverse needs of its clients. Whether it's large-scale industrial pipe production or specialized custom projects, the machinery is designed to accommodate various requirements, making it a versatile and attractive option for manufacturers across different sectors.

As part of the company's ongoing efforts to provide comprehensive solutions, Pipe Production Line also offers after-sales support and maintenance services. This ensures that clients can maximize the efficiency and longevity of their equipment, further solidifying the company's reputation for customer-focused service.

The release of this new line of machinery is a significant milestone for Pipe Production Line, marking the next step in its journey to redefine the pipe production industry. By leveraging cutting-edge technology, prioritizing sustainability, and prioritizing customer-centric solutions, the company is well-positioned to make a lasting impact on the global market.

Overall, Pipe Production Line's latest release is a testament to its unwavering commitment to excellence and innovation. With a strong focus on advancing the industry, the company is poised to set new standards for pipe production equipment and solidify its position as a leader in the market. As the global demand for high-quality and efficient pipe production solutions continues to grow, Pipe Production Line is well-prepared to meet these needs and exceed expectations.

Company News & Blog

Effective Plastic Melter Densifier for Waste Management

Plastic pollution has become a major concern in recent years, with an increasing focus on finding sustainable solutions to manage and reduce plastic waste. One innovative technology that is making waves in the industry is the Plastic Melter Densifier, a groundbreaking product that is revolutionizing the way we recycle and manage plastic waste.The Plastic Melter Densifier, developed by a leading sustainable technology company, is a state-of-the-art machine that has the ability to process and recycle a wide range of plastic waste, including PET, HDPE, LDPE, and many others. By using a combination of heat and pressure, the machine is able to convert plastic waste into dense, compact blocks that can be easily stored, transported, and reused for a variety of applications.This cutting-edge technology is playing a crucial role in helping to reduce the environmental impact of plastic waste, which has been a growing concern for many years. With the Plastic Melter Densifier, companies and organizations have the ability to significantly reduce their carbon footprint by efficiently recycling their plastic waste, rather than sending it to landfills or incinerators.The company behind the Plastic Melter Densifier is a leader in sustainable technology solutions, with a strong commitment to environmental stewardship and innovation. Their team of experts and engineers have worked tirelessly to develop and refine the Plastic Melter Densifier, ensuring that it meets the highest standards of performance, efficiency, and environmental sustainability.In addition to the environmental benefits of the Plastic Melter Densifier, the machine also offers significant economic advantages for businesses and organizations. By efficiently processing and recycling plastic waste, companies can reduce their waste disposal costs, while also creating new revenue streams by selling the recycled plastic blocks to manufacturers and other businesses.Furthermore, the recycled plastic blocks produced by the Plastic Melter Densifier can be used in a wide range of applications, including the manufacturing of new plastic products, construction materials, and even fuel. This adds another layer of versatility and value to the machine, making it an essential tool for companies looking to improve their environmental impact and bottom line.The company's commitment to sustainability and technological innovation has garnered widespread recognition and success, with the Plastic Melter Densifier receiving accolades and awards for its groundbreaking approach to plastic waste management. The company's dedication to improving the environment and promoting a circular economy has positioned them as a leader in the sustainable technology industry, and their products are quickly gaining traction in markets around the world.With plastic pollution continuing to be a significant global challenge, the need for innovative solutions like the Plastic Melter Densifier has never been greater. By offering a sustainable, efficient, and cost-effective way to manage and recycle plastic waste, this groundbreaking technology is helping to pave the way towards a more sustainable future for our planet.In conclusion, the Plastic Melter Densifier is a game-changing technology that is revolutionizing the way we recycle and manage plastic waste. With its advanced processing capabilities, economic advantages, and environmental benefits, this innovative machine is helping to address the urgent need for more sustainable solutions to plastic pollution. As the company continues to lead the way in the sustainable technology industry, the future looks brighter for our planet and the generations to come.

Ultimate Guide to Plastic Pelletizing Line for Extruders

Extruder Plastic Pelletizing Line: A New Milestone in Plastic RecyclingIn today's world, where environmental concerns are at the forefront of global discussions, finding innovative solutions for plastic recycling has become more important than ever. With the increasing production and consumption of plastics, the need for efficient and sustainable recycling processes has become a pressing issue. This is where the new Extruder Plastic Pelletizing Line from [company name] comes into play, offering a groundbreaking solution for plastic recycling.The Extruder Plastic Pelletizing Line, developed by [company name], is a state-of-the-art system that is designed to convert plastic waste into high-quality plastic pellets. These pellets can then be used as raw material for the production of new plastic products, thus closing the loop on plastic waste and contributing to a circular economy. The line is capable of processing a wide range of plastic materials, including polyethylene, polypropylene, polystyrene, and PET, making it a versatile solution for various plastic recycling needs.One of the key features of the Extruder Plastic Pelletizing Line is its high efficiency and energy-saving design. The line is equipped with advanced extrusion and pelletizing technology, allowing for continuous and reliable operation while minimizing energy consumption. This not only makes the line more cost-effective to operate but also reduces its environmental impact, making it a sustainable choice for plastic recycling facilities.Furthermore, the Extruder Plastic Pelletizing Line is designed with user-friendliness in mind. Its intuitive control system and automated processes make it easy to operate and maintain, reducing the need for extensive training and specialized technical skills. This makes the line accessible to a wide range of users, from small-scale recycling facilities to large industrial operations.In addition to its technical capabilities, the Extruder Plastic Pelletizing Line is backed by the expertise and experience of [company name]. With a proven track record in the design and manufacturing of plastic recycling equipment, the company has a deep understanding of the challenges and opportunities in the industry. This knowledge has been instrumental in the development of the Extruder Plastic Pelletizing Line, ensuring that it meets the highest standards of performance and reliability.[Company name] is committed to providing comprehensive support and services for the Extruder Plastic Pelletizing Line, including consulting, installation, and maintenance. This ensures that customers can make the most of their investment in the line, maximizing its productivity and longevity.The introduction of the Extruder Plastic Pelletizing Line represents a new milestone in the field of plastic recycling. With its advanced technology, efficiency, and user-friendly design, the line offers a promising solution for the challenges of plastic waste management. By converting plastic waste into high-quality pellets, the line supports a more sustainable and circular approach to plastic production and consumption.As the demand for plastic recycling solutions continues to grow, the Extruder Plastic Pelletizing Line from [company name] is set to play a key role in shaping the future of the industry. With its cutting-edge technology and commitment to sustainability, the line is a testament to [company name]'s dedication to innovation and environmental responsibility.

Advanced Co Extruder Technology for Optimized Production

Co Extruder revolutionizes the manufacturing industry with its cutting-edge technology and innovative solutions. The company, with its headquarters in the United States, has been a pioneer in the development of extrusion equipment for various industries including food, pharmaceutical, and plastic manufacturing.With a focus on providing high-quality and efficient extrusion solutions, Co Extruder has constantly pushed the boundaries of technology to meet the ever-evolving needs of its customers. The company's commitment to innovation and excellence has made it a trusted partner for businesses around the world.The latest product from Co Extruder, the Co-Extrusion Machine, is set to transform the way manufacturers approach the extrusion process. This state-of-the-art machine brings together advanced technology and intelligent design to deliver unmatched performance and precision.One of the key features of the Co-Extrusion Machine is its ability to perform co-extrusion, a process that involves extruding two or more materials simultaneously to create a single, multi-layered product. This capability opens up a world of possibilities for manufacturers, allowing them to create complex and unique products with varying properties and functionalities.The machine's unique co-extrusion technology is made possible by its precision-engineered components, including specialized screws, die heads, and control systems. These components work together seamlessly to ensure that the materials are processed with the highest level of accuracy and consistency.In addition, the Co-Extrusion Machine is equipped with advanced monitoring and control systems that allow operators to fine-tune the process in real-time, ensuring optimal product quality and performance. This level of control is unprecedented in the industry and sets a new standard for extrusion equipment.Another notable feature of the Co-Extrusion Machine is its versatility. The machine is capable of handling a wide range of materials, including thermoplastics, elastomers, and food-grade ingredients. This flexibility makes it an ideal solution for manufacturers looking to diversify their product offerings and enter new markets.Furthermore, the Co-Extrusion Machine is designed with efficiency in mind. Its energy-efficient operation and minimal waste generation make it a sustainable choice for environmentally conscious companies. By reducing material consumption and energy usage, the machine helps businesses lower their operational costs while reducing their environmental footprint.The introduction of the Co-Extrusion Machine represents a significant milestone for Co Extruder and the extrusion industry as a whole. With its unparalleled performance, versatility, and sustainability, the machine is poised to drive innovation and create new opportunities for manufacturers across the globe.To support its customers in maximizing the potential of the Co-Extrusion Machine, Co Extruder offers comprehensive technical support and training programs. This ensures that operators are able to fully leverage the capabilities of the machine and achieve the best possible results.In conclusion, Co Extruder's Co-Extrusion Machine is a game-changer for the manufacturing industry. Its advanced technology, precision engineering, and unmatched versatility make it a must-have for businesses looking to stay ahead of the competition. With its commitment to innovation and customer satisfaction, Co Extruder continues to set the bar for excellence in the extrusion equipment market.

Plastic Extrusion Line: A Detailed Overview of Profile Extrusion Manufacturing

The plastic extrusion line is a vital component in the manufacturing process for a wide range of plastic products. It is an indispensable tool for companies like {Company Name}, which specializes in the production of high-quality plastic extrusion equipment. The company has been at the forefront of the industry for many years, providing innovative solutions to meet the needs of their clients.The plastic extrusion line is a complex piece of machinery that is used to create a variety of plastic products, including pipes, tubes, and sheets. It works by forcing raw plastic material through a heated barrel and then shaping it into the desired form through a die. This process allows for the production of products with consistent dimensions and high precision.{Company Name} has developed a reputation for delivering cutting-edge plastic extrusion lines that are highly efficient and reliable. Their equipment is designed to meet the demands of modern manufacturing processes, delivering high outputs and consistent quality. With a focus on innovation and continuous improvement, {Company Name} has established itself as a leader in the industry, providing solutions that meet the unique needs of their clients.The plastic extrusion lines offered by {Company Name} are designed to be versatile and adaptable, capable of producing a wide range of products with different shapes, sizes, and materials. This flexibility allows their clients to expand their product offerings and meet the diverse needs of their customers. {Company Name} takes pride in delivering solutions that are tailored to the specific requirements of each client, providing them with the tools they need to succeed in a competitive market.In addition to their commitment to delivering high-quality equipment, {Company Name} also provides comprehensive support and service to their clients. They understand the importance of keeping production lines running smoothly and efficiently, and offer a range of services to help their clients maintain and optimize their plastic extrusion lines. This includes regular maintenance, troubleshooting, and training to ensure that their clients can maximize the performance and lifespan of their equipment.The success of {Company Name} and their plastic extrusion lines can be attributed to their dedication to innovation and customer satisfaction. They work closely with their clients to understand their needs and develop solutions that meet their specific requirements. This customer-centric approach has allowed {Company Name} to build long-lasting relationships with their clients, earning their trust and loyalty.As the demand for plastic products continues to grow, the need for reliable and efficient plastic extrusion lines will only increase. {Company Name} is well-positioned to meet this demand, leveraging their expertise and experience to deliver solutions that enable their clients to succeed in a competitive market. With a commitment to excellence and a focus on continuous improvement, {Company Name} will continue to lead the way in the plastic extrusion industry for years to come.

High-Quality Water Pipe Making Machine for Efficient Production

Water Pipe Making Machine Revolutionizes the Manufacturing Process[Company Name], a leading manufacturer of industrial machinery, has recently introduced a state-of-the-art water pipe making machine that has revolutionized the manufacturing process for water pipes. This innovative machine has the capability to produce high-quality water pipes with increased efficiency and reduced production costs, making it a game-changer in the industry.The [Company Name] water pipe making machine is designed to streamline the entire manufacturing process, from the initial raw material input to the final output of finished water pipes. The machine is equipped with advanced technology that ensures precision and accuracy in each step of the production process, resulting in water pipes that meet the highest quality standards.One of the key features of the water pipe making machine is its ability to handle a wide range of raw materials, including various types of plastics, metals, and composites. This versatility allows manufacturers to produce water pipes with different specifications and properties to meet the specific requirements of their customers.In addition to its flexibility in raw material usage, the water pipe making machine is also known for its high production capacity. The machine is capable of producing a large volume of water pipes in a relatively short amount of time, allowing manufacturers to meet the demands of their customers in a timely manner.Furthermore, the water pipe making machine is designed with efficiency in mind. It is equipped with automated systems that optimize the production process, minimize material waste, and reduce labor costs. This not only results in cost savings for manufacturers but also contributes to a more sustainable and environmentally friendly manufacturing operation.The introduction of the water pipe making machine has been met with great enthusiasm from the industry. Manufacturers are excited about the potential of this machine to transform their production capabilities and improve their competitiveness in the market. With its advanced technology and cost-saving benefits, the machine is expected to become an essential asset for water pipe manufacturers around the world.[Company Name] is committed to providing innovative solutions for the industrial machinery industry, and the water pipe making machine is a testament to that commitment. The company has a long-standing reputation for delivering high-quality and reliable machinery, and the introduction of the water pipe making machine further solidifies its position as a leader in the industry.As the demand for high-quality water pipes continues to grow, the water pipe making machine is poised to play a significant role in shaping the future of water pipe manufacturing. Its advanced capabilities, efficiency, and cost-saving benefits make it a valuable investment for manufacturers looking to stay ahead of the competition and meet the evolving needs of the market. With [Company Name] leading the way in innovation, the future of water pipe manufacturing looks brighter than ever.

Efficient and Eco-Friendly Bottle Washing Machine for Recycling

[Company Introduction][Company Name] is a leading manufacturer and supplier of innovative and efficient recycling machinery for the plastic industry. With a strong focus on sustainability and environmental responsibility, [Company Name] has been developing cutting-edge solutions to help businesses reduce their carbon footprint and contribute to a cleaner and healthier planet.One of the company's flagship products is the Pet Bottle Washing Machine, a state-of-the-art system designed to effectively clean and recycle PET bottles, which are widely used for packaging beverages, food, and personal care products. The machine is equipped with advanced technology and features that ensure thorough cleaning and efficient processing of PET bottles, making it an essential asset for recycling facilities and companies looking to adopt sustainable practices.[News Content]In a concerted effort to address the growing concerns about plastic waste pollution and promote sustainable recycling practices, [Company Name] has launched a new and improved version of its Pet Bottle Washing Machine. This upgraded machine is set to revolutionize the recycling industry by offering enhanced performance, energy efficiency, and cost-effectiveness.The new Pet Bottle Washing Machine is equipped with advanced washing and drying mechanisms that can effectively remove contaminants and impurities from PET bottles, ensuring that the recycled material meets high-quality standards. With its high-speed processing capabilities, the machine can handle large volumes of PET bottles with ease, making it an ideal solution for recycling facilities and manufacturers looking to minimize their environmental impact.One of the key features of the new machine is its energy-efficient design, which not only reduces operational costs but also aligns with [Company Name]'s commitment to sustainability. By optimizing water and electricity consumption, the Pet Bottle Washing Machine helps businesses lower their carbon footprint and contribute to a greener future.Furthermore, the machine is built to withstand the rigors of heavy-duty industrial use, ensuring long-term durability and reliability. Its user-friendly interface and automated operations make it easy to operate, allowing businesses to streamline their recycling processes and improve overall efficiency.The launch of the new Pet Bottle Washing Machine underscores [Company Name]'s dedication to pushing the boundaries of recycling technology and providing innovative solutions that address the pressing environmental challenges of our time. By offering a more efficient and sustainable way to process PET bottles, the company is empowering businesses to embrace a circular economy and reduce their reliance on virgin plastics.In addition to the new machine, [Company Name] also offers comprehensive training and technical support to ensure that customers can maximize the potential of their recycling equipment. This commitment to customer satisfaction and ongoing innovation has established [Company Name] as a trusted partner for businesses striving to make a positive impact on the environment.As the demand for sustainable recycling solutions continues to grow, [Company Name] remains at the forefront of the industry, leading the way with its innovative products and unwavering commitment to environmental stewardship. With the launch of the new Pet Bottle Washing Machine, the company is poised to set new standards for efficiency, reliability, and sustainability in the recycling sector, inspiring businesses to embrace a more eco-friendly approach to plastic waste management.

High-Quality Crusher Blades for Efficient Material Shredding

Crusher Blade Revolutionizes Industrial Shredding TechnologiesIn the realm of industrial grinding and shredding, the Crusher Blade has emerged as a game-changer that is transforming the way materials are processed. Manufactured by a leading engineering company, this innovative blade has been generating buzz and receiving widespread acclaim for its exceptional performance and durability.With a history of excellence and a commitment to pushing the boundaries of engineering, the company behind the Crusher Blade has been a driving force in the evolution of industrial shredding technologies. Specializing in the design and manufacture of precision engineering components for various industries, they have gained a strong reputation for delivering cutting-edge solutions that meet the highest standards of quality and reliability.The Crusher Blade represents a milestone in the company's journey of innovation and advancement. Designed to withstand the toughest of conditions, it is a testament to their unwavering dedication to developing products that exceed expectations. The blade's exceptional cutting efficiency and long-lasting performance have set a new benchmark for industrial shredding, making it a preferred choice for businesses looking to optimize their operations and enhance productivity.One of the key features of the Crusher Blade is its superior strength and durability. Made from high-quality materials and engineered to withstand heavy-duty usage, it has proven to be resilient against wear and tear, delivering consistent performance over extended periods of operation. Its robust construction and sharp cutting edge ensure that it can effectively handle a wide range of materials, including plastics, rubber, wood, and metal, making it a versatile and reliable tool for industrial processing needs.Furthermore, the design of the Crusher Blade has been optimized for efficiency and precision. Its unique configuration and advanced cutting technology enable it to achieve exceptional results with minimal energy consumption, ultimately leading to cost savings for businesses. This high level of performance has made it an invaluable asset for industries such as recycling, manufacturing, and waste management, where the need for efficient material processing is critical.Apart from its impressive technical capabilities, the Crusher Blade also offers ease of maintenance and compatibility with various shredding machines. Its universal design allows for seamless integration with different systems, offering businesses the flexibility to upgrade their existing equipment and benefit from the blade's superior cutting performance. Moreover, the company provides comprehensive support and technical assistance to ensure that customers can optimize the use of the Crusher Blade for their specific applications.The impact of the Crusher Blade on industrial shredding operations has been significant, with businesses experiencing tangible improvements in their processing efficiency and overall productivity. It has enabled them to streamline their operations, maximize the utilization of resources, and achieve higher throughput, ultimately driving profitability and competitiveness in their respective markets.Looking ahead, the company remains committed to advancing the capabilities of the Crusher Blade and exploring new avenues for innovation in industrial shredding technologies. With a strong focus on research and development, they are continuously working on enhancing the blade's performance and expanding its application potential, with the goal of addressing evolving industry needs and market demands.In conclusion, the Crusher Blade has emerged as a disruptive force in the realm of industrial shredding, offering a compelling solution for businesses seeking to elevate their material processing capabilities. Backed by a company with a proven track record of engineering excellence, it epitomizes the pursuit of innovation and the relentless pursuit of engineering excellence. As industries continue to evolve, the Crusher Blade is well-positioned to play a pivotal role in shaping the future of industrial shredding technologies.

Top Pulverizer and Grinder Options for Effective Material Processing

Pulverizer And Grinder, a company at the forefront of manufacturing high-quality industrial machinery, has firmly established itself as a leading player in the market. With a commitment to innovation and excellence, the company has consistently delivered top-of-the-line products that cater to the diverse needs of its customer base.Specializing in the production of pulverizers and grinders, the company has gained a strong reputation for its unwavering dedication to quality and customer satisfaction. Its state-of-the-art manufacturing facilities, equipped with the latest technology and machinery, enable it to produce cutting-edge equipment that meets the highest industry standards.The company's pulverizers and grinders are widely utilized across various industries, including pharmaceuticals, chemicals, food processing, and more. Known for their reliability, efficiency, and durability, these machines have become the go-to choice for businesses seeking to enhance their production processes and maximize output.One of the key factors that sets Pulverizer And Grinder apart from its competitors is its relentless pursuit of innovation. The company continuously invests in research and development to stay ahead of the curve and introduce advanced features and capabilities in its products. This commitment to innovation has allowed it to stay abreast of evolving industry trends and consistently meet the changing needs of its customers.Moreover, Pulverizer And Grinder takes pride in its team of highly skilled engineers and technicians who possess in-depth knowledge and expertise in the field of industrial machinery. Their wealth of experience enables them to design and manufacture pulverizers and grinders that not only meet but exceed the expectations of clients, setting new benchmarks in terms of performance and reliability.In addition to its impressive product range, the company also places a strong emphasis on providing excellent customer service. With a focus on building long-term partnerships with its clients, Pulverizer And Grinder offers comprehensive support and maintenance services to ensure that its equipment continues to deliver optimal performance throughout its lifespan. This commitment to customer satisfaction has helped the company forge strong relationships with a loyal and growing customer base.As a testament to its dedication to quality, Pulverizer And Grinder adheres to stringent quality control measures at every stage of the manufacturing process. From sourcing the finest raw materials to conducting rigorous quality checks on the finished products, the company ensures that only the best-in-class equipment leaves its facilities. This unwavering commitment to quality has earned Pulverizer And Grinder the trust and confidence of its clients, further solidifying its position as a respected industry leader.Looking ahead, Pulverizer And Grinder is poised to continue its journey of growth and success, driven by its core values of excellence, innovation, and customer satisfaction. With a steadfast focus on staying ahead of the competition and delivering unparalleled value to its clients, the company is well-positioned to further expand its presence in the global market.In conclusion, Pulverizer And Grinder stands out as a company that exemplifies the highest standards of quality, innovation, and customer service in the field of industrial machinery manufacturing. With a strong track record of success and a vision for the future, the company is set to achieve even greater milestones and solidify its position as a powerhouse in the industry.

High-quality PVC Twin Screw Extruder for Efficient Plastic Processing

Pvc Twin Screw Extruder is a revolutionary machine that is set to transform the plastic manufacturing industry. This innovative equipment is designed to provide a more efficient and cost-effective solution for companies looking to produce high-quality PVC products.The Pvc Twin Screw Extruder utilizes advanced technology and state-of-the-art engineering to deliver exceptional performance and reliability. With its twin screw design, this extruder offers increased output capacity and improved material mixing, resulting in a superior finished product.One of the key features of the Pvc Twin Screw Extruder is its versatility. This machine is capable of processing a wide range of PVC materials, including rigid PVC, flexible PVC, and PVC compounds. This flexibility makes it an ideal choice for companies looking to diversify their product offerings or expand into new markets.In addition to its versatility, this extruder is also designed with efficiency in mind. Its twin screw configuration allows for a more consistent and thorough mixing of materials, which ultimately leads to reduced waste and increased productivity. The machine's precise temperature and pressure control further contribute to its efficiency, ensuring that the finished products meet the highest quality standards.Furthermore, the Pvc Twin Screw Extruder is built with durability and longevity in mind. Its robust construction and high-quality components make it a reliable and long-lasting investment for any manufacturing operation. Additionally, the machine's user-friendly interface and automated controls make it easy to operate and maintain, further adding to its appeal.The company behind the Pvc Twin Screw Extruder, {}, is a renowned leader in the plastic machinery industry. With a history of delivering cutting-edge solutions and exceptional customer service, {} has established itself as a trusted partner for companies seeking to enhance their manufacturing capabilities.{}'s commitment to innovation and quality is exemplified in the Pvc Twin Screw Extruder. This machine is the result of extensive research and development, as well as a deep understanding of the evolving needs of the plastic manufacturing industry. By continuously investing in new technologies and refining its products, {} is dedicated to helping its customers stay ahead of the competition.In addition to its focus on technology, {} is also committed to providing comprehensive support and service to its customers. The company's team of highly skilled engineers and technicians are readily available to provide installation, training, and ongoing maintenance for the Pvc Twin Screw Extruder, ensuring that its customers can maximize the benefits of this state-of-the-art equipment.Overall, the Pvc Twin Screw Extruder represents a significant advancement in the plastic manufacturing industry. Its combination of versatility, efficiency, and reliability makes it a valuable asset for companies looking to elevate their production capabilities and deliver superior PVC products to the market.With the backing of a reputable and innovative company like {}, the Pvc Twin Screw Extruder is poised to make a lasting impact on the industry and empower manufacturers to achieve new levels of success. As the demand for high-quality PVC products continues to grow, this groundbreaking machine is well-positioned to become an essential tool for companies striving to meet and exceed industry standards.

Industry News: Advanced PE Pipe Machine Revolutionizing Manufacturing Processes

The demand for high-quality and efficient PE pipe machines has been growing in the global market, and with the latest advancements in technology, () has introduced a cutting-edge PE pipe machine that is set to revolutionize the industry. With its commitment to innovation and excellence, () has established itself as a leader in the manufacturing of plastic extrusion machinery, and its latest PE pipe machine is a testament to its dedication to providing superior solutions for its customers.The new PE pipe machine from () is designed to meet the increasing demand for high-performance and cost-effective solutions in the production of PE pipes. With its advanced technology and precision engineering, this machine offers superior performance and efficiency, making it an ideal choice for manufacturers looking to enhance their production capabilities.The () PE pipe machine is capable of producing a wide range of PE pipes with varying specifications, making it suitable for a diverse range of applications. Whether it is for water distribution, gas transportation, or industrial purposes, this machine is designed to deliver exceptional results with unmatched reliability.One of the key features of the () PE pipe machine is its high-speed production capability, allowing manufacturers to increase their output without compromising on quality. This is made possible by the machine's state-of-the-art design and advanced control system, which ensures consistent and precise production at every stage.In addition to its high-speed production capability, the () PE pipe machine also offers a user-friendly interface, making it easy to operate and maintain. This is particularly beneficial for manufacturers who are looking to streamline their production processes and reduce downtime, ultimately leading to improved productivity and profitability.Furthermore, the () PE pipe machine is equipped with advanced automation features, allowing for seamless integration with other production systems. This not only enhances efficiency but also provides greater flexibility in meeting different production requirements, thereby ensuring a competitive edge in the market.As a leading manufacturer of plastic extrusion machinery, () is committed to providing comprehensive support and services to its customers. With a team of skilled engineers and technicians, the company offers installation, training, and after-sales support to ensure that its customers can maximize the performance of the PE pipe machine.The introduction of the () PE pipe machine is set to have a significant impact on the global market for PE pipes, as manufacturers seek to upgrade their production capabilities with the latest technology and equipment. With its superior performance, efficiency, and reliability, this machine is poised to set new standards for the industry and establish () as a trusted partner for manufacturers worldwide.In conclusion, the () PE pipe machine represents a significant advancement in the manufacturing of PE pipes, offering unparalleled performance, efficiency, and reliability. With its cutting-edge technology and advanced features, this machine is well-positioned to meet the growing demand for high-quality and cost-effective solutions in the global market. As () continues to spearhead innovations in plastic extrusion machinery, the introduction of this machine underscores its commitment to excellence and customer satisfaction.